MOULDING

Plastic products, it’s what we do!

Avid’s state-of-the-art plastic injection moulding facility houses the latest, fully-electric Sumitomo machines.

These machines assist us in manufacturing high-quality products efficiently, for a range of industries.

Operating under a quality management system, we manufacture products to the highest standards with stringent quality assurance procedures in place to ensure complete customer satisfaction and traceability.

What is plastic injection moulding?

Injection moulding is the most commonly used and most cost-effective process of manufacturing plastic products.

An injection moulding machine is used which has a heated barrel, that plastic pellets are fed into via a hopper at the top of the machine.

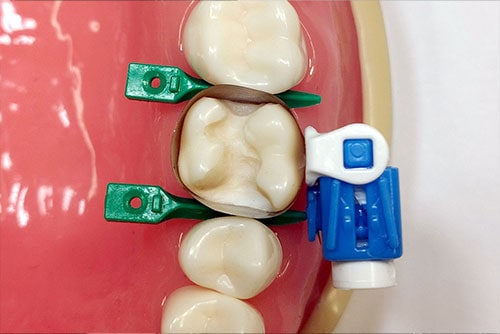

What can be made?

You can make almost anything from the plastic injection moulding process – plastic furniture, food & beverage packaging, medical devices, toys, clips… really any product that can be made from a mould, the options are endless!

Injection moulding is a high production manufacturing method with a low labour cost and generates little to no waste – see what we do with our plastic waste here.

Talk to the team at Avid to discuss your plastic injection moulding requirements.