Tooling

AVID’s engineering facility houses industry leading equipment & experts

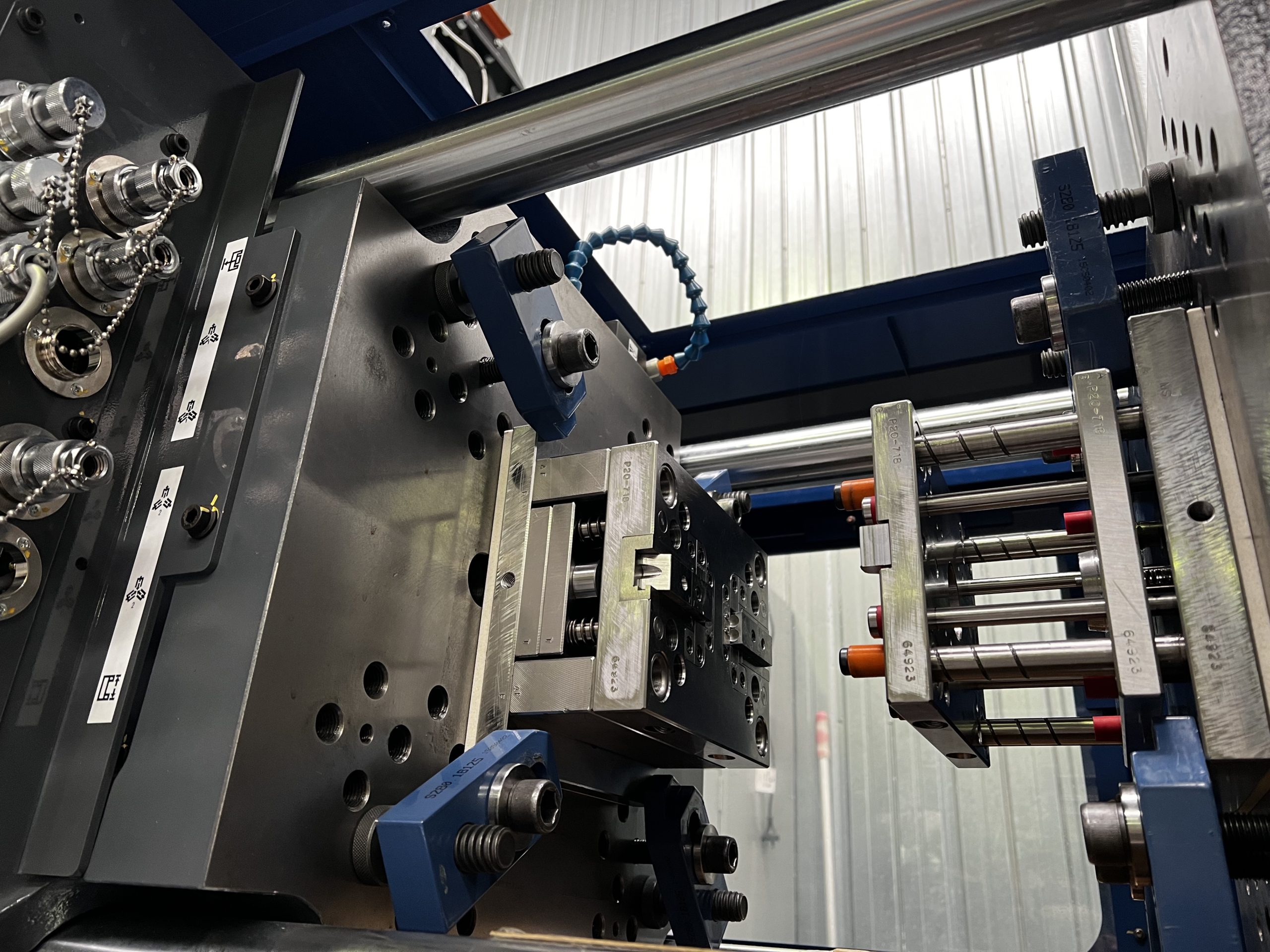

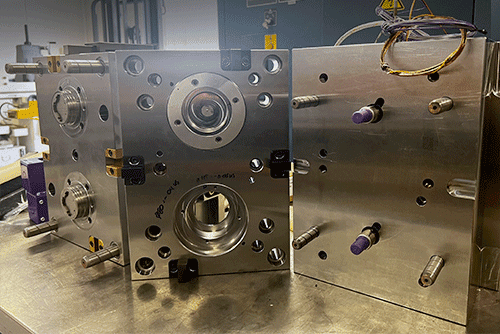

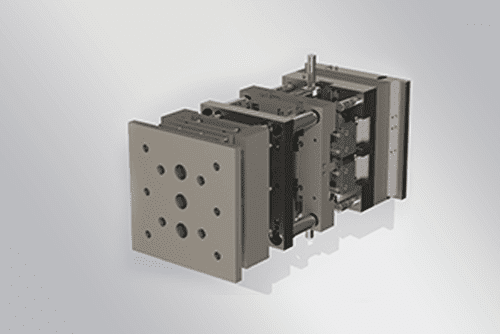

It all starts with well built ‘Tools’ or ‘Moulds’. These are a necessity to the success of an injection moulding project.

New or existing tooling, we’ll take projects on at any stage.

In-house tool maintenance, repairs and modifications ensure your tooling is maintained to the highest standards.

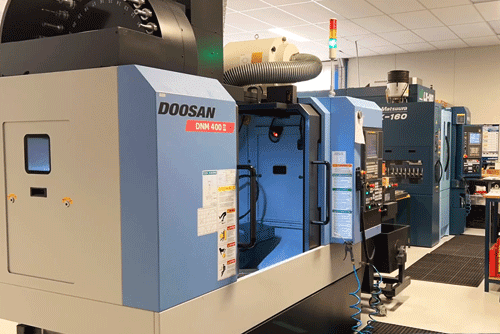

Our toolroom houses two industry leading CNC machines to assist us in building quality tools for quality products!

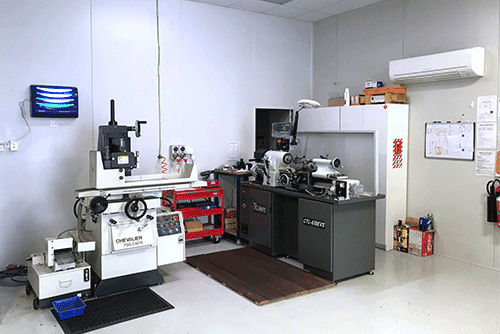

Our toolroom is well resourced housing all that we need to build and maintain tools without reliance on contractors.

Tools are assembled using high quality components from leading brands such as Mastip & Husky which increase tooling longevity, lasting millions of cycles.

In-house tool design ensures the right tool is built for the job. Expected volumes, product features, materials, part lines, are all taken into account when finding the best solution.

Talk to the team at Avid to discuss your plastic injection moulding requirements.